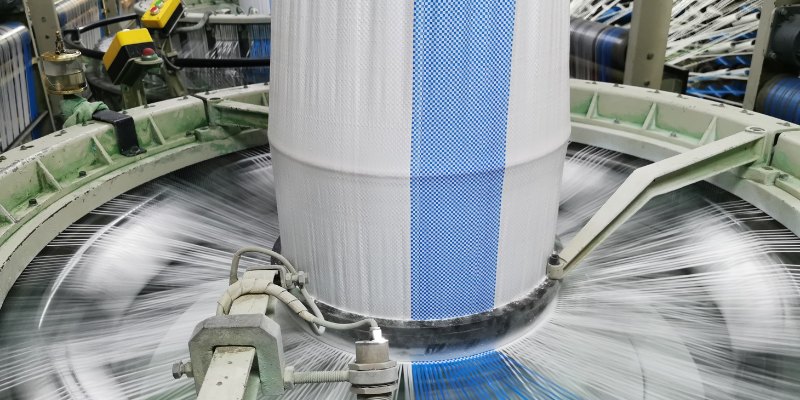

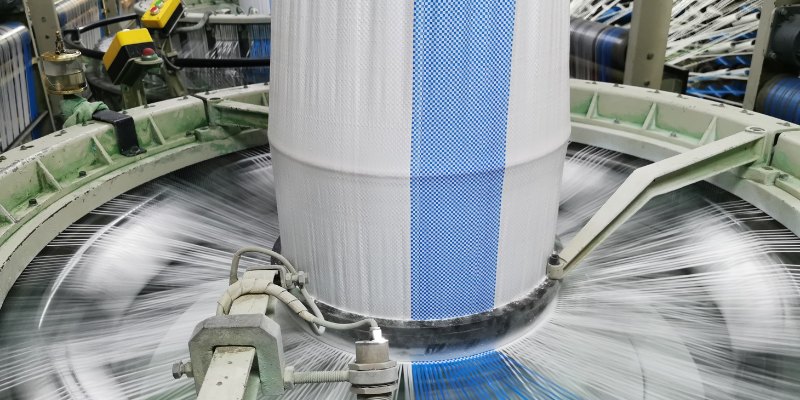

Woven fabrics, a remarkable category of technical textiles, hold immense importance in various industries. These fabrics have been designed to meet the unique demands of technical applications. They offer exceptional strength, durability, and versatility. With their extensive features and customization options, woven materials have become indispensable in industries that demand precise engineering and technical expertise.

In this article, we will delve into the importance of woven fabrics, exploring their essential characteristics and highlighting their crucial role in advanced industries.

Now that we’ve covered why woven fabrics are important, let’s take a look at some of their applications in advanced industrial manufacturing processes.

Now that we’ve covered why woven fabrics are important, let’s take a look at some of their applications in advanced industrial manufacturing processes.

Why are Woven Fabrics Important?

Strong and Durable

PP woven fabric is known for its high strength and durability, making it suitable for a wide range of industrial applications. It can withstand heavy loads and resist tearing or puncturing, ensuring the safe transportation and storage of various goods and materials. These fabrics provide unmatched structural integrity and resilience, making them ideal for industrial applications. In fact, woven fabrics act as robust reinforcements in critical applications across various industries, as they can bear substantial stress.Flexibility

PP woven fabric offers excellent flexibility, allowing it to be easily molded, folded, or sewn into different shapes and sizes. This flexibility makes it adaptable to various manufacturing requirements, such as the production of bags, sacks, covers, and liners.Lightweight

Despite its strength, PP woven fabric is relatively lightweight compared to other materials. This characteristic makes it a preferred choice in industries where weight reduction is important, such as packaging, transportation, and construction.Water and Moisture Resistance

PP woven fabric has inherent water and moisture resistance properties, which make it suitable for applications where protection against moisture or water ingress is required. It is commonly used for manufacturing products like geotextiles, tarpaulins, and agricultural covers.Highly Versatile

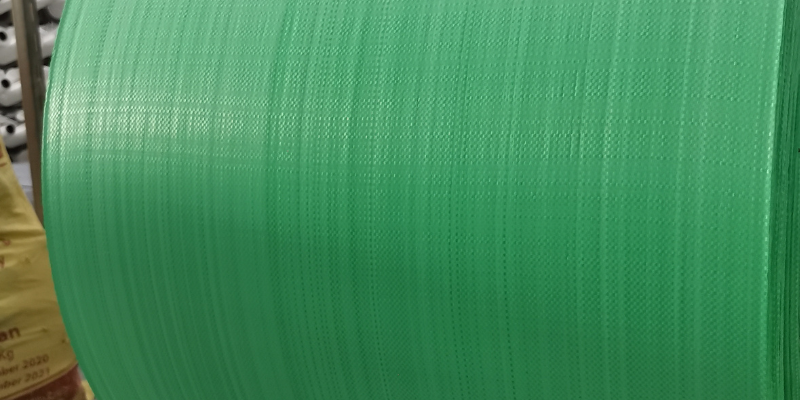

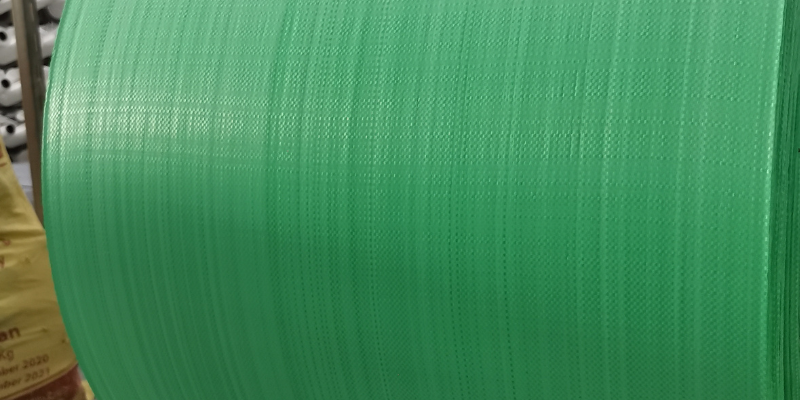

Another reason why woven fabrics are so important in various industries is their remarkable versatility and customization options. These fabrics can be tailored to cater to the specific requirements of each industry, ensuring optimal performance and functionality. At Anita Plastics, we offer a diverse range of options, including a variety of colors, fabric widths, and specific weights (GSM), so manufacturers can choose the most suitable fabric for their precise needs. But it doesn’t stop there. Woven materials can also be customized with specific features to enhance their functionality. Whether it’s anti-skid, crushed or flat, or square weave options, these fabrics provide enhanced grip, smooth surfaces, or precise dimensions as per the technical requirements.Cost Effective

PP woven fabric is relatively inexpensive compared to other materials, making it a cost-effective choice for industrial manufacturing processes. Its affordability, combined with its durability and versatility, contributes to its widespread use in various industries. They strike an excellent balance between cost and performance, allowing manufacturers to achieve optimal results without breaking their budgetary constraints. And with the diverse range of coating finishes, substrate lamination options, and printing technologies provided by Anita Plastics, manufacturers have the power to create tailored solutions that meet both their technical and financial requirements.Recyclability

Polypropylene, the primary material used in PP woven fabric, is recyclable. This aspect is essential for sustainable manufacturing practices, as it enables the reuse and reduction of waste. Recycling PP woven fabric helps minimize environmental impact and conserve resources. Overall, the importance of PP woven fabric in industrial manufacturing processes lies in its strength, durability, flexibility, lightweight nature, chemical and water resistance, cost-effectiveness, and recyclability. These characteristics make it an essential material for applications such as packaging, transportation, agriculture, construction, and many others across a wide range of industries.Where are Woven Fabrics Used?

Now that we’ve covered why woven fabrics are important, let’s take a look at some of their applications in advanced industrial manufacturing processes.

Now that we’ve covered why woven fabrics are important, let’s take a look at some of their applications in advanced industrial manufacturing processes.